-

-

Japanese

Toyota

Land Cruiser 70 73 75 77 (1984~1994)

Land Cruiser 71 76 78 79 (1999~2018)

Land Cruiser 80 (1992~1997)

Land Cruiser 100 (1997~2007)

Land Cruiser 105 (1998~2002)

Land Cruiser 200 (2008~2021)

Lexus LX4700 (1998-2007)

Lexus LX4500 (1995~1998)

Lexus LX5700 (2008~2018)

Lexus GX460 (2002~2009)

Lexus GX470 (2009~2023)

Land Cruiser Prado 120 (2002~2009)

Land Cruiser Prado 150 (2009~2023)

FJ Cruiser (2003~2017)

Hilux Vigo (2005~2015)

Hilux Revo (2015~)

Hiace 200 (2004~2016)

Hiace 300 (2016~)

Fortuner (2004-2015)

Fortuner (2015-)

4Runner(2002-2009)

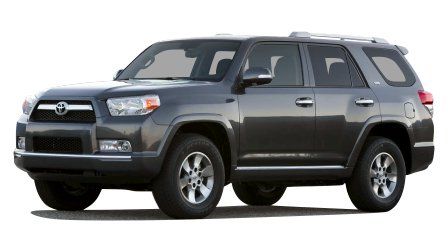

4Runner 2009-2018

Tacoma (1995~2003)

Tacoma (2004~2015)

Tacoma(2015~)

Tundra

INNOVA (2004~2022)

HARRIER-ACU35 MCU35(2000-2003)

HARRIER-MCU15(1998-2003)

-

Side gear/ Pinion/ Spider

Jul 23,2024

Side gear, pinion, and spider are three essential components in the mechanical system of various machines, including automobiles, motorcycles, bicycles, and industrial machinery. Each of these parts plays a unique role in the proper functioning of the machine, working together to ensure smooth and efficient operation. In this article, we will explore the functions and characteristics of side gear, pinion, and spider, as well as their importance in different types of machinery.

Side gear is a type of gear that is used to transmit power between two parallel shafts in a machine. It is typically located on one of the shafts and meshes with another gear, known as the pinion, which is mounted on the other shaft. The side gear is usually larger in size compared to the pinion gear, allowing it to transfer more power and torque. Side gears are commonly used in automotive differential systems, where they help distribute power between the two drive wheels of a vehicle.

Pinion is a gear with a small number of teeth that meshes with a larger gear, such as a side gear, to transfer power and motion between two shafts. The pinion gear is usually mounted on a shaft that is connected to a motor or other power source, allowing it to drive the larger gear. Pinions are commonly found in various mechanical systems, including steering systems, power tools, and industrial machinery. They are designed to provide high-speed rotation and efficient power transmission, making them essential components in many types of machines.

Spider is a type of gear that connects multiple shafts in a machine, allowing them to rotate together while maintaining their individual speeds and directions. The spider gear is typically used in differential systems, where it helps distribute power between the drive wheels of a vehicle. In this application, the spider gear connects the side gears on the two drive axles, allowing them to rotate at different speeds while ensuring that power is evenly distributed between the wheels. Spider gears are also used in industrial machinery and other types of mechanical systems where multiple shafts need to be connected and synchronized.

In conclusion, side gear, pinion, and spider are three essential components in the mechanical systems of various machines, playing crucial roles in power transmission, motion control, and speed synchronization. These gears work together to ensure smooth and efficient operation of different types of machinery, from automobiles and motorcycles to industrial equipment and power tools. Understanding the functions and characteristics of side gear, pinion, and spider is essential for engineers, mechanics, and machine operators to maintain and repair machines effectively, ensuring their optimal performance and longevity.

PREVIOUS:

ENQUIRY NOW

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Leave Your Message