-

-

Japanese

Toyota

Land Cruiser 70 73 75 77 (1984~1994)

Land Cruiser 71 76 78 79 (1999~2018)

Land Cruiser 80 (1992~1997)

Land Cruiser 100 (1997~2007)

Land Cruiser 105 (1998~2002)

Land Cruiser 200 (2008~2021)

Lexus LX4700 (1998-2007)

Lexus LX4500 (1995~1998)

Lexus LX5700 (2008~2018)

Lexus GX460 (2002~2009)

Lexus GX470 (2009~2023)

Land Cruiser Prado 120 (2002~2009)

Land Cruiser Prado 150 (2009~2023)

FJ Cruiser (2003~2017)

Hilux Vigo (2005~2015)

Hilux Revo (2015~)

Hiace 200 (2004~2016)

Hiace 300 (2016~)

Fortuner (2004-2015)

Fortuner (2015-)

4Runner(2002-2009)

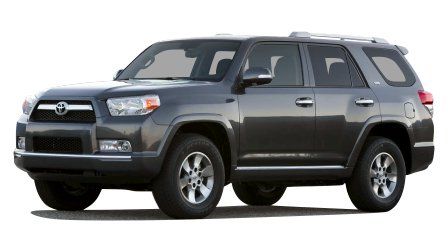

4Runner 2009-2018

Tacoma (1995~2003)

Tacoma (2004~2015)

Tacoma(2015~)

Tundra

INNOVA (2004~2022)

HARRIER-ACU35 MCU35(2000-2003)

HARRIER-MCU15(1998-2003)

-

ABOUT US

A professional manufacturer of differential parts for SUV, Pickups and Light/Heavy Duty Trucks.

Speed and precision dance: high-speed ink printing slotting die-cutting stacking machine printing industrial revolution

High-speed ink printing slotting die-cutting stacking machine description

High-speed ink printing slotting die-cutting stacking machines represent the advanced technology and innovation of the modern printing industry. They are key equipment in the printing production process, enabling efficient and high-quality printing, slotting, die-cutting and stacking operations. This article will introduce the main features and advantages of high-speed ink printing slotting die-cutting stacking machines.

Main features:

High-speed production: High-speed ink printing slotting die-cutting stacking machines perform printing, slotting, die-cutting and stacking operations at excellent speeds, greatly improving production efficiency.

Precision and consistency: These machines are equipped with advanced control systems to ensure that each printed product has consistent high quality and can achieve precise slotting and die-cutting.

Automation: High-speed ink printing slotting die-cutting stacking machines can achieve a highly automated production process, reducing the need for human intervention and reducing labor costs.

Versatility: These machines have a variety of functions and can adapt to a variety of different printing and packaging needs, from simple carton making to complex packaging box manufacturing.

Space saving: Due to the compact design, these machines take up less space, making them suitable for a variety of printing factories.

Advantages:

Increase production efficiency: The high-speed operation and automation functions of the high-speed water-based printing slotting die-cutting stacking machine can significantly increase the output of the printing line and reduce production time.

Reduce costs: By reducing manual intervention and scrap rates, these machines can reduce production costs and improve production benefits.

Excellent quality: The precise control and high degree of automation of the machine ensure the high quality and consistency of each printed product.

Flexibility: The high-speed water-based printing slotting die-cutting stacking machine can be adjusted according to different printing and packaging needs, making it an ideal choice for a variety of products.

Environmental protection: The use of efficient equipment can reduce energy consumption and waste generation, helping to reduce the impact on the environment.

Conclusion:

High-speed water-based printing slotting die-cutting stacking machines are key equipment in the modern printing industry. They bring great advantages to printing companies by improving production efficiency, reducing costs and providing excellent printing quality. Not only that, they also make positive contributions to environmental protection. If you want to stay competitive in the printing industry, high-speed water-based printing slotting die-cutting stacking machines are used to improve your production process and product quality.

ENQUIRY NOW

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Leave Your Message